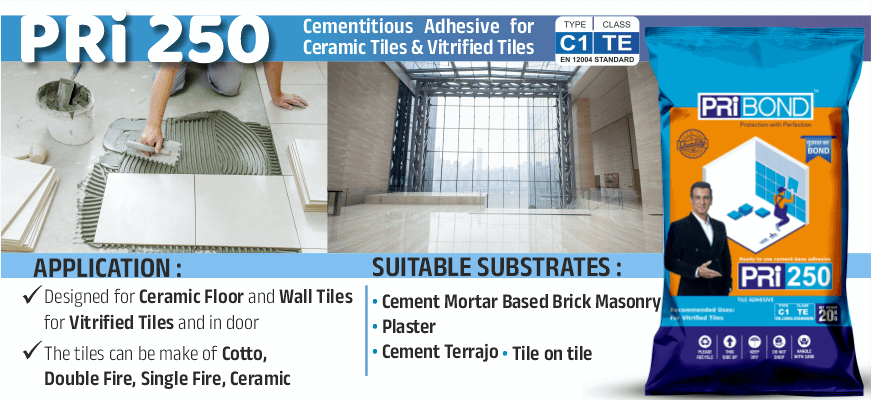

PRi 250

PRiBOND’S PRi250 is a Silica Sand based tile adhesive, that has excellent results for high resistance laying of ceramic tiles on floor, walls on cement-based substrates. It is workable up to 10 mm thickness and the formulation ensure optimum – performance for tile setters. It is absolutely reliable and has its base in superiority of its conception.

CEMENTATIOUS ADHESIVE FOR CERAMIC TILES & VITRIFIED TILES

Areas of Application

Designed for ceramic floor and wall tiles for outdoor and indoor. The tiles can be made of cotta, double fire, single fire, ceramic. Floors and walls, for internal and external use, in domestic, industrial and commercial applications also in areas subject to freezing.

Features & Benefits

- Eco – friendly,

- High – performance laying, ideal for use in industrial and commercial applications

- Mineral adhesive for high adhesion,

- PRi250 contains recycled raw materials

- PRi250 develops an extended open and adjustability time meaning even highly porous tiles can be quickly and safely laid on very absorbent substrates.

- Thicknesses up to 10 mm

Preparation of Substrate

- The substrates must be free from dust, oil and grease, must be in dry condition and free from any rising dampness, the residual traces of cement, lime and paint, shall be totally scraped & removed

- The substrate must be stable without cracks, must have already been completely cured. Undulated areas must be corrected with suitable smoothing and finishing products.

Packing:

20 Kg Bag. Grey colour

Method of Application

- In general, cement – based substrates must be free from dust, oil and grease, dry and free from any rising damp, with no loose, flaky or imperfectly anchored parts such as residual traces of cement, lime and paint, which must be totally removed.

- The substrate must be stable and without cracks, must have already completed curing hygrometric shrinkage and must present suitable mechanical resistance levels. Undulated areas must be corrected with suitable smoothing and finishing products.

Screeds and plasters which present a weak crystalline structure in the initial mm of thickness which can be easily abraded must be consolidated by means of Primer, the professional, water – base depth consolidant, to be applied with one or more coatings and according to the instructions, until a surface has been obtained which is still absorbent but compact.

On screeds and plasters which are compact but highly absorbent, in warm climates and with direct ventilation, it is advisable to apply in advance Primer, a professional, concentrated, water base, surface insulation product, with one or more coatings and according to the instructions, to reduce water absorption and to improve spreadability of the adhesive.

- Prepare PRi250 in a clean container, first of all pouring in a quantity of water equal to approximately 5 ltr. of that which will be required.

- Gradually add PRi250 to the water in the container, mixing the paste from the bottom upwards with a low – rev (400 RPM / min.) helicoidal agitator. Then add more water until the desired consistency is obtained, the mixture must be homogeneous and without any lumps. For best results and to mix larger quantities of adhesive, a stirring device with vertical blades and slow rotation is recommended.

- Specific polymers with high – dispersion properties ensure that PRi250 is immediately ready for use. The amount of water to be added, indicated on the packaging. It is possible to obtain mixtures with a more or less thixotropic consistency, depending on the type of application.

IMPORTANT

Adding extra water does not improve the workability of the product, may cause shrinkage in the plastic phase of drying and result in less effective final performance with a reduction in compressive strength and adhesion to the substrate.

- PRi250 should be applied with a suitable toothed spreader, to be chosen according to the size and characteristics of the rear surface of the tiles. It is best to use the smooth part of the trowel to spread a fine initial layer, pressing down hard so as to obtain maximum adhesion to the substrate and to regulate water absorption, after which the thickness can be adjusted as

required by tilting the spreader at an angle. - Spread the adhesive over a surface area which will allow for laying of the surface materials within the indicated open time and check for suitability of the adhesive at regular intervals, the open time may vary considerably during the same operation, depending on various factors such as exposure to sunlight, air currents, absorbency of the substrate, temperature and relative

humidity of the atmosphere. - Press down each tile to allow for complete, uniform contact with the adhesive. In the case of laying in environments subject to heavy traffic or in outdoor locations, the double – spread technique must be used, to ensure 100 % coverage of the rear of the tiles.

- In general, ceramic tiles do not require preliminary treatment, however these materials should properly anchor to the substrate or which may modify the absorption characteristics of the tiles.

Approximately 30-35 Sq. ft for 20 Kg. bag.

square notch trowel for a bed thickness of 5mm.

12 months with original packing in dry storage condition.

Use Gloves. Non-Toxic.