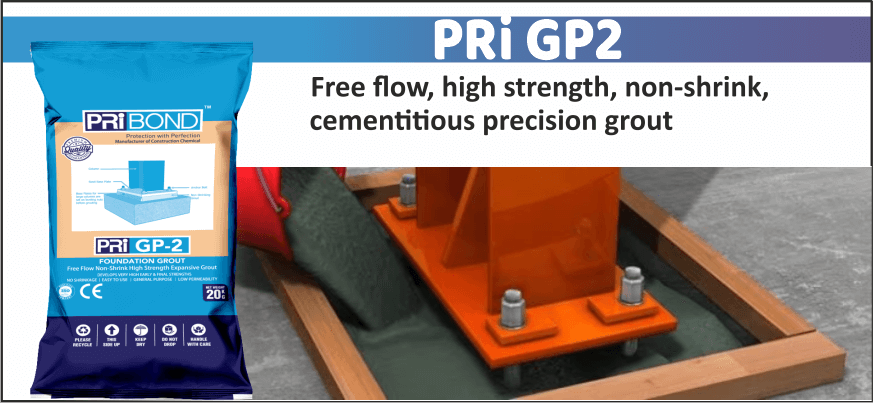

PRi GP 2

PRiBOND’S PRi GP-2 is used for precision grouting where it is essential to withstand static and dynamic loads. Typical applications would be the grouting of base plates of turbines, compressors, boiler feed pumps etc., It can also be used for anchoring a wide range of fixings.

These include masts, anchor bolts and fence posts.

FREE FLOW, HIGH STRENGTH, NON-SHRINK, CEMENTITIOUS PRECISION GROUT

- PRi GP2 is supplied as a ready to use dry powder. The addition of a controlled amount of clean water produces a free flowing, non-shrink grout for gap thicknesses up to 100mm.

- PRi GP2 is a blend of Portland cement, graded fillers and chemical additives which impart controlled expansion in the plastic state whilst minimising water demand. The low water demand ensures high early strength. The graded fillers are designed to assist uniform mixing and produce a consistent grout.

Packaging

PRi GP2 is supplied in 20 kg moisture resistant bags.

Fire

PRi GP2 is non-flammable.

Additional information

For further details about the use and selection of grouts refer to the PRiBOND Information module entitled ‘Precision grouting in the Construction industry’.

- Gaseous expansion system compensates for shrinkage and settlement in the plastic state

- No metallic iron content to cause staining

- Pre-packed material overcomes onsite batching variations

- Develops high early strength without the use of chlorides

- High ultimate strength ensures the durability of the hardened grout

- Free flow ensures high level of contact with load bearing area

- Foundation surface

The substrate surface must be free from oil, grease or any loosely adherent material. If the concrete surface is defective or has laitance, it must be cut back to a sound base. Bolt holes and fixing pockets must be blown clean of any dirt or debris. - Pre-soaking

Several hours prior to placing, the concrete substrates should be saturated with fresh water. Immediately before grouting takes place any free water should be removed with particular care being taken to blow out all bolt holes and pockets. - Base plate

It is essential that this is clean and free from oil, grease or scale. Air pressure relief holes should be provided to allow venting of any isolated high spots. Always use appropriate size of trowel with respect to the tile size and the density of the tile. - Levelling shims

If these are to be removed after the grout has hardened, they should be treated with a thin layer of grease. - Formwork

The formwork should be constructed to be leakproof. This can be achieved by using foam rubber strip or mastic sealant beneath the constructed formwork and between joints. In some cases, it is practical to use a sacrificial semi-dry sand and cement formwork. The formwork should include outlets for pre-soaking. - Unrestrained surface area

This must be kept to a minimum. Generally, the gap width between the perimeter formwork and the plate edge should not exceed 150mm on the pouring side and 50mm on the opposite side. It is advisable, where practical, to have no gap at the flank sides.

For best results a mechanically powered grout mixer should be used. When quantities up to 50kg are used, a heavy-duty slow speed drill (400-500 rpm) fitted with a paddle is suitable. Larger quantities will require a heavy-duty mixer. To enable the grouting operation to be carried out continuously, it is essential that sufficient mixing capacity and labour are available. The use of a grout holding tank with provision to gently agitate the grout may be required.

The quantity of clean water required to be added to a 20kg bag to achieve the desired consistency is given below:

Pourable: 3.30 litres

Flowable: 3.60 litres

The selected water content should be accurately measured into the mixer. The total content of the PRi GP2 bag should be slowly added and continuous mixing should take place for 5 minutes. This will ensure that the grout has a smooth even consistency.

- At 300C place the grout within 20 minutes of mixing to gain full benefit of the expansion process.

- PRi GP2 can be placed in thicknesses up to 100mm in a single pour when used as an underplate grout.

- For thicker sections it is necessary to fill out PRi GP2 with well graded silt free aggregate to minimise heat build-up. Typically, a 10mm aggregate is suitable. 50 – 100% aggregate by weight of PRi GP2 can be added.

- Any bolt pockets must be grouted prior to grouting between the substrate and the base plate.

- Continuous grout flow is essential. Sufficient grout must be prepared before starting. The time taken to pour a batch must be regulated to the time to prepare the next one

On completion of the grouting operation, exposed areas should be thoroughly cured. This should be done by the use of Con- cure WB curing membrane, continuous application of water and/or wet hessian.

PRi GP 2 grout should be removed from tools and equipment with clean water immediately after use. Cured material can be Removed mechanically, or with reawakens.

Compressive Strength Age (days) | (BS 1881 : Part 116, 1983) Compressive strength (N/mm²) consistency (W/P – 0.19) Flowable (W/P 0.18) | Pourable (W/P 0.165) |

| 1 | 24 | 27 |

| 3 | 45 | 54 |

| 7 | 55 | 66 |

| 28 | 65 | 78 |

Compressive strength with Addition of aggregates | Compressive Strength (N/mm²) W/P 0.18 % of aggregates (IS 516 – 1959) |

| Age (days) | 50% 75% 100% |

| 1 | 28 30 32 |

| 3 | 50 52 55 |

| 7 | 60 62 68 |

| 28 | 70 75 78 |

Tensile Strength 3.5N/mm² @ 28 days

(W/P – 0.18)

Pull-out bond strength 17 N/mm² @ 7 days

(W/P – 0.18) 20 N/mm² @ 28 days

Time for expansion Start: 20 minutes

(After mixing) Finish: 120 minutes

Fresh wet density approximately 2220kg/m³ depending on actual consistency used

Young’s modulus (ASTM D469 – 94) 28 kN/mm²

Dynamic load resistance Specimens of PRi GP-2 remained undamaged even after subjecting them

To alternate loads of 5N/mm² & 25N/mm² at the rate of 500 cycles / minute

For two million cycles.

Coefficient of thermal expansion 11 x 10 -6/ 0 C

Unrestrained expansion 2 – 4 % in the plastic state enables to overcome shrinkage.

Pressure to restrain 0.004 N/mm² approx.

Flow Characteristics The maximum distance of flow is governed by the gap width and the head of

The grout. Typical data for flow design assuming grout is poured immediately

After mixing is given in the table below:

Grout Consistency | Gap width (mm) | 50mm Head | 100mm Head | 250mm Head |

Flowable | 30 | 350 | 1000 | 1500 |

| 40 | 500 | 1500 | 2000 |

| 50 | 900 | 2000 | 3000+ |

Low temperature working

When the air or contact surface temperatures are 100C or below on a falling thermometer, warm water (30 – 400C) isrecommended to accelerate strength development. For ambient temperature below 100C the formwork should be kept in place for at least 36 hours. Normal precautions for winter working with cementitious material should then be adopted.

High temperature working

At ambient temperatures above 400 C, cool water (below 200C) should be used for mixing the grout prior to placement

Allowance should be made for wastage when estimating quantities required. The approximate yield per 20 kg bag for different consistency is:

Consistency Pourable Flowable

Yield (litres) 10 10.64

PRi GP2 has a shelf life of 6 months if kept in a dry store in sealed bags. If stored in high temperature and high humidity locations, the shelf life may be reduced.

- PRi GP2 is alkaline and should not come into contact with skin and eyes. Inhalation of dust during mixing should be avoided.

- Gloves, goggles and dust mask should be worn.

- If contact with skin occurs, it shall be washed with water. Splashes to eyes should be washed immediately with plenty of clean water and medical advice sought.